The challenges of developing AGV Robots

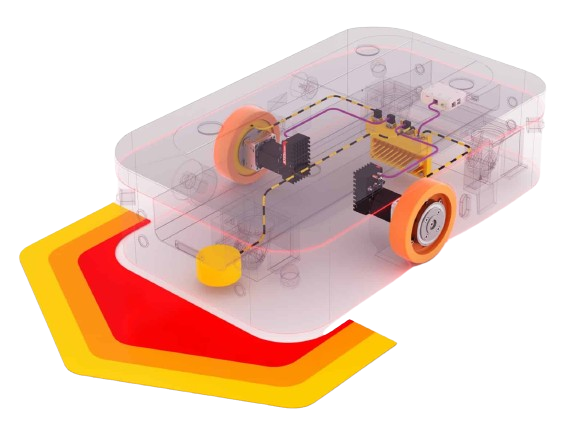

Engineers developing autonomous guided vehicle/autonomous mobile robot (AGV/AMR) applications face many challenges, not the least of which is specifying servo drives, servo motors, gearboxes, encoders, and braking options. Ideally, for cost and convenience purposes, it’s often preferable to have such drive system components offered as a package from a single supplier. However, many problems can result from using off-the-shelf drivetrain components designed for stationary machines and not for AGV/AMR applications.

Meeting requirements demanded by AGV / AMR Applications

Generally designed for operation in climate-controlled environments, standard off-the-shelf drive systems created for stationary machines are rarely able to meet the strict and precise temperature, vibration, size, weight, radial-load capacity, and control requirements demanded by AGV/AMR applications. In addition to these design restrictions, standard drive systems tend to lack adequate drive protection for AGV/AMR applications.

Drive System components – offered as a package from a single supplier

For these reasons, among others, many AGV/AMR manufacturers are looking for solutions that fit their unique needs. Along with solving problems presented by standardized drivetrain components, drive systems made specifically for AGV/AMR applications offer a whole host of benefits. Having a variety of components that work together to optimize mobile applications is well worth the investment.

The benefits of Drive Systems specifically designed for mobile applications

- Wide Temperature Range: AGV/AMR optimized drive system component designs include fan-less heat dissipation.

AGV/AMR systems offer a wide range of temperatures, from -40 degrees Celsius to 85 degrees Celsius, to allow for heat dissipation. - Robust Design: Systems design for AGV/AMR applications use strong connectors that can withstand vibration and shock.

- Range of Supported Voltages: AGV/AMR systems operate at significantly lower input voltages that can accommodate variations.

- Better Features: Mobile AGV/AMR devices require improved features for overcurrent protection, monitoring, and warning, which are offered by systems specifically designed with these in mind.

- High-Performance Motor Control: Better-performing motor controls allow for more precise speed and position control to regulate acceleration and limit abrupt movements.

Supported voltages range from 20 V to 60 V +-10% — due to batteries.AGV/AMR systems require sinusoidal commutated and not block commutated, a bandwidth of current loop of at least 1kHz, PWM frequency of at least 16kHz. Better control enables higher precision for speed and position control.

- Wide Speed Range: Ready-to-use wheel drives allow for a wider speed range and smooth operation.

- Compact Size and Ease of Assembly: Gear motors designed for AGV/AMR applications are more compact than their standardized counterparts. Whereas standardized gear motors can be difficult to assemble due to a lack of pluggable power connectors, gear motors designed for AGV/AMR applications have pluggable connectors, so they are easier to assemble.

- High Radial Load Capacity: They also have a higher radial load capacity, at 25 kN.

- Less Noise: Gear motors made for AGV/AMR systems operate with helical-toothed gears, which are quieter than gears on off-the-shelf applications.

- Safety: Utilizing gear motors specifically designed for AGV/AMR applications is a cost-effective solution to meet functional safety requirements without using expensive functional safety encoders. Instead, these drives include a cost-effective safety torque off (STO) feature, enabled by a DSP that checks the circuits every microsecond and an external PLC that monitors the optocoupler required for STO isolation.Because AGV/AMR applications involve movement, there are many challenges with using off-the-shelf drivetrain components designed for stationary machines. It is better to utilize components specifically designed for AGV/AMR applications. These work together to create safer, more effective, and more precise movements with AGV/AMR devices.

Looking for a ready-to-use wheel drive system designed and optimized for the requirements of automated guided vehicles and autonomous mobile robots?