Introduction

As robots become more sophisticated, they are able to take on a growing number of industrial processes. Six-degrees-of-freedom (6DoF) robots are capable of the complex movements that enable them to perform well in many complicated industrial tasks like palletizing, handling, gluing and welding. 6DoF robots can lift and deftly manipulate heavy payloads, precisely moving them with complex geometry.

Because of their great capabilities and flexibility, 6DoF robots are assigned many different tasks using a wide variety of tools. However, taking advantage of the capabilities of these robots requires precise re-calibration every time a new tool is introduced. Re-calibration is often time-consuming and inaccurate, inhibiting smooth operation of industrial processes and delaying production.

Servotronix has created an effective teach-position method that quickly calibrates a new tool used by a 6DoF robot without relying on manufacturer measurements or external sensors. The method is easy, accurate, and useful in practical applications.

Calibration

A 6DoF robot holds and moves a tool in order to perform a task. To achieve satisfactory performance, the robot must know the exact location of the tool while it works. Each time a different tool is attached, the robot must be precisely re-calibrated.

There are different methods for calibrating 6DoF robots. Touching reference parts, using distance sensors and employing laser interferometry are just a few. Also, external sensors such as camera systems can be attached to various robot locations in order to acquire the precise position of a reference object from which the robot can be calibrated.

These methods are time-consuming and complicated. Servotronix has developed a simpler method that has already achieved excellent results. We describe the method below.

Determining the Tool Center Point

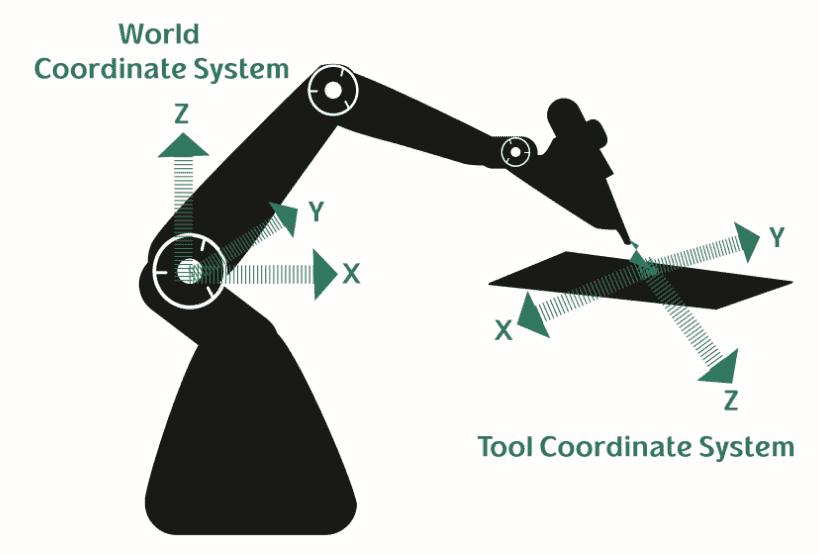

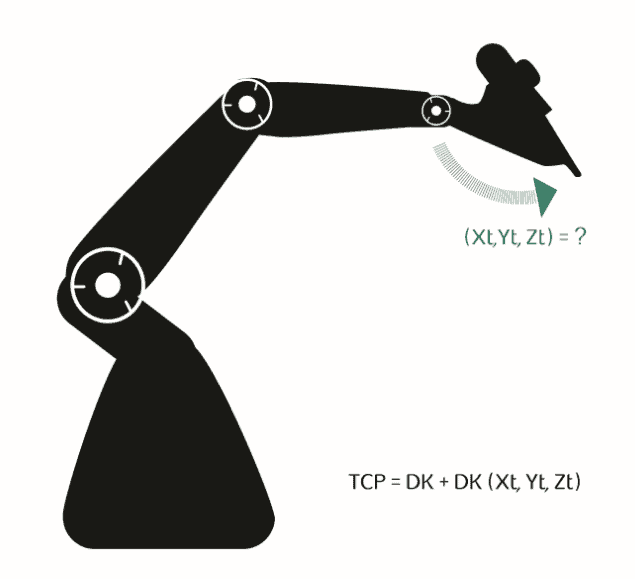

Kinematic calibration methods are used to determine the tool center point (TCP), the point in relation to which all robot positioning is defined. The TCP is defined relative to the world coordinate system, the Cartesian coordinate system for any point in the world, which always remains stationary with respect to the robot.

The tool coordinate system defines the position and orientation of the tool, and has its zero-position at the tool’s center point (TCP). The TCP of the robot moves to programmed positions as it executes Cartesian motion. Changing the tool changes the tool coordinate system, requiring re-calibration to enable the new TCP to accurately reach the target.

In many robot applications, the motion trajectories of the TCP represent complex paths in the robot’s working space, typically a straight-line path with some orientation change of the tool by the robot. The tool itself might need to be replaced occasionally or even frequently. Each time the tool is replaced, a new set of geometric parameters must be determined and assigned before operations can be resumed.

In most industrial applications, teach-position is the most practical means for writing robot tasks. With this method, tool parameters have to be available (usually from the manufacturer) with high accuracy. The angular offsets of the tool (yaw, pitch and roll) and its Cartesian offset are necessary for generating straight-line paths with controlled orientation of the tool.

Unfortunately, quite often, the operator is expected to identify the tool geometry under certain constraints: (1) no a priori knowledge on tool dimensions from the manufacturer; (2) no available hardware assistance; (3) no knowledge about how the tool is mounted on the robot flange. Faced with these constraints, the operator must undertake time-consuming calibration procedures every time the tool is changed.

Exact Estimation Made Simple

Servotronix has developed a method for quick, exact estimation of tool geometry without external sensors, vision or other aids, and without dismounting the tool. In this teach-position method, the operator simply brings the 6DoF robot’s TCP to several different positions/orientations which are then automatically input to Servotronix tool-dimension estimation algorithms. The algorithms quickly determine precise calibrations of the new tool, promptly readying it for use.

The accuracy of this calibration method improves with more tool positions/orientations that are used as input to the algorithms. Our experiments show that whereas using an inverted homogeneous matrix does not necessarily lead to the desired results, using least-squares estimation results in values that lead to precise calibration.

The Servotronix Method

Our tests were performed using a 6DoF robot with a mounted tool, six Servotronix high-performance CDHD servo drives and the Servotronix softMC controller. Our method involves an analytical calculation and does not require the dismounting of the tool. XYZ dimensions alone are estimated and the tool tip is assumed to be in constant Cartesian location.

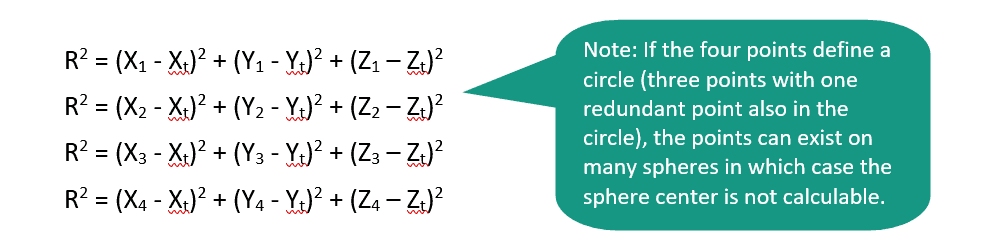

It is axiomatic that all robot configurations that point to the same location must lay on a sphere with tool tip in the center of the sphere:

Taking measurements of points that lie on the sphere enables calculation of the TCP.

where t represents the center

- R2 = (X – Xt)2 + (Y – Yt)2 + (Z – Zt)2

In Equation (1) we have four unknown parameters (R, Xt, Yt, Zt). The values of X, Y, and Z are calculated by direct kinematics. To reach acceptable accuracy, our method requires at least four points to define a sphere. Therefore, four such configurations would be:

By using equation subtraction, not only do we eliminate the unknown variable R, but we clear all non-linear components in the equations. This leaves a set of polynomial equations of degree 1 which can be solved by linear least-squares fitting. Taking more than four points results in more equations and higher accuracy.

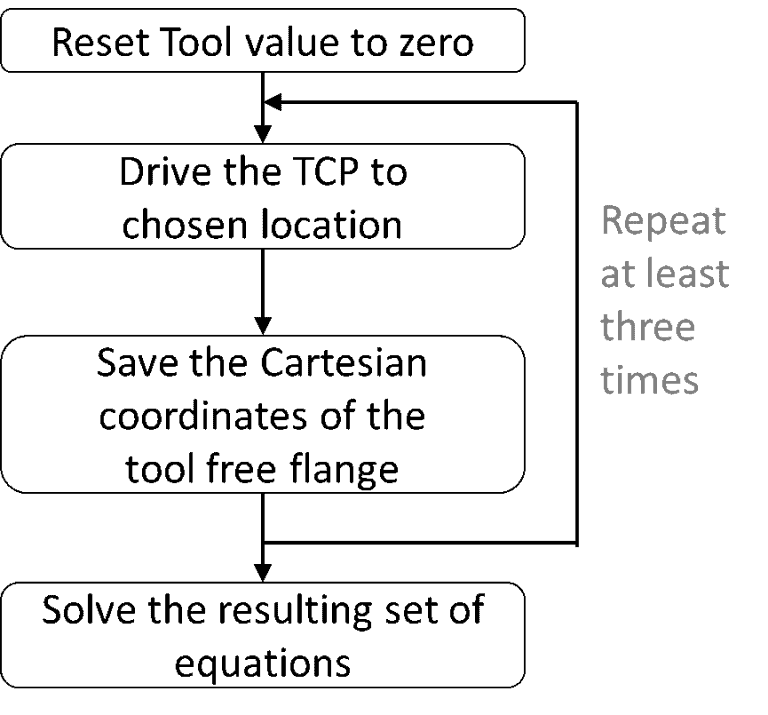

The step-by-step method takes only a few minutes requiring the taking of at least four measurements as follows:

Summary

The Servotronix method is quick, accurate and inexpensive, enabling tool calibration without dismounting the tool. The method can be performed simply without dedicated hardware, saving time and effort whenever a new tool is mounted. Machine builders can easily implement the method and enjoy quick, precise and virtually cost-free re-calibration of 6DoF robot tools that will enhance smooth operation and speed up production in a wide variety of applications.